Design

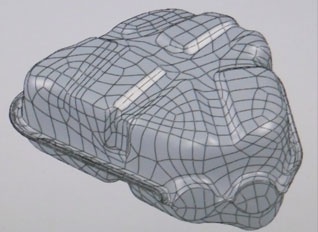

All Klarius emissions products are designed utilising the latest 3D CAD software with reference to OEM samples and blueprints of the desired component. Achieving or exceeding the quality and efficiency levels of the OEM part is the minimum standard for Klarius, so via this methodology we can deliver a part of exceeding quality.

Components are developed to suit specific marques, models and production years to ensure an exact fit. Every product is fit tested to the applicable vehicle, which ensures that when it comes to installing a Klarius component on the ramp, it will integrate seamlessly with the intended vehicle.

Rapid prototyping, 3D laser scanning, custom fabricated fitment templates and an in-house tooling further aids development work – allowing Klarius engineers to deliver parts to market on reduced lead times.

Testing

All applicable Klarius components are type-approved in-house to EU legislative standards, which provides a minimum benchmark of quality to end users. Furthermore, all components are independently tested to standards set by regulatory bodies such as the VCA and TÜV to ensure compliant noise and emissions levels. Again, the objective is to provide a proven product that attain OEM characteristics for these parameters.

In addition, all Klarius parts are fit tested on applicable vehicles, to ensure they can be easily installed on the intended vehicle. That’s why we supply a ‘Fit First Time’ guarantee across our range.

Testing is carried out at the in-house Klarius emissions test track, which is certified to ISO-10844. The track features specialised tarmac to ensure very accurate noise test readings, allowing independent test houses to certify Klarius products before they are sent for production and delivered to market.

An integrated approach

Klarius continually invests in research and development, which means that we can deliver parts to market faster to support vehicles on the road.

Types of vehicles supported by Klarius include:

- City cars & superminis

- Saloons & hatchbacks

- MPVs & compacts

- Sports cars & coupes

- SUVs & 4x4s

- Light Commercials

- Classics

Klarius operates a demand driven product development policy, which actively searches for gaps in the market or reacts to the component requirements of motorists. This ensures a truly balanced product range, where rare parts and high demand parts can be supplied simultaneously on short lead times.

With our integrated approach from initial development to market release, you can be sure your new Klarius emissions component will offer consistent quality and performance.